3c. When Things Don't Work: Diagnostics (Display test,

Lamp test, Solenoid test, Switch test, Sound test)

Where Bally took the approach that the boot-up diagnostics were

very important and game diagnostics were not, Williams took the opposite

approach that boot-up diagnostics were *not* important but

game diagnostics were! Hence where 1977-1985 Bally games

don't really have a lamp, display, coil or switch test,

Williams system3 to system7 games do have good versions

of these tests (assuming that the game in question will

boot up properly!)

System4 to System7 Diagnostics.

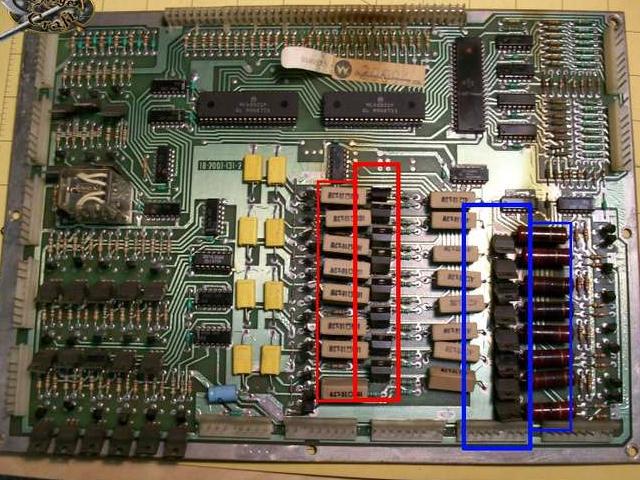

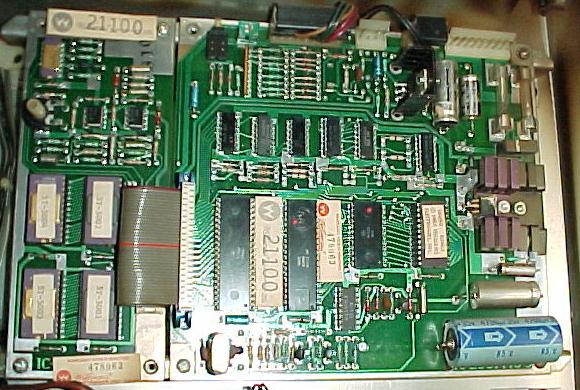

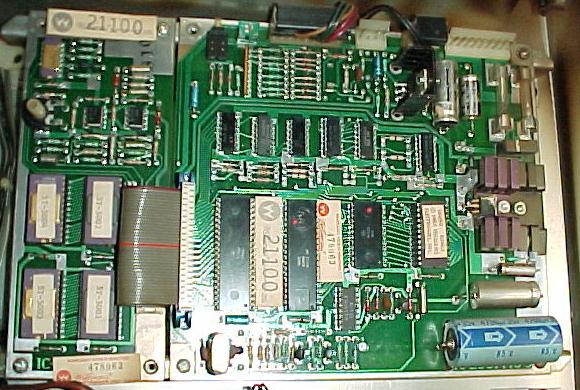

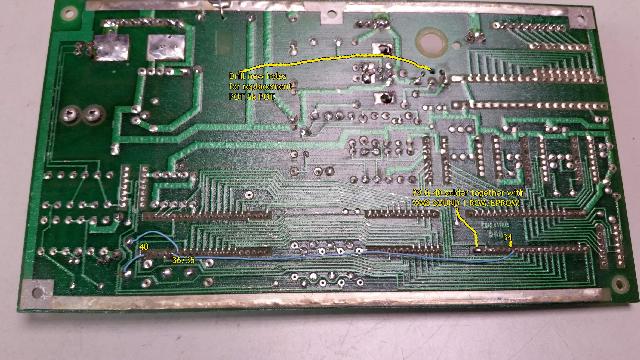

The diagnostic firmware is located in the "Flipper ROMs"

at IC20 and IC17. Remember our previous discussion of this,

system4 uses yellow flipper ROMs,

system6 uses green flipper ROMs, and system7 uses blue flipper ROMs.

System3 (white flipper ROMs) diagnostics are different to

access, so see the section on that below.

But the system4 to system7 diagnostics are pretty easy to use

following these instructions. These diagnostics will

test the score displays, the lamp matrix, the switch matrix

(and on system7 a separate test for sound).

For system4 to system7 games,

to use the internal game diagnostics,

the game will need to boot up into attract mode.

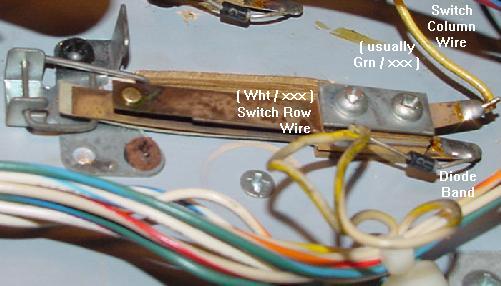

To access the switch diagnostics, there are a pair of

switches inside the coin door that need to be accessed.

Here are the steps used to access the diagnostics on system4 to system7

games:

- Turn the game on and allow it to go into attract mode.

- With the coin door open,

press the coin door Auto-up/Manual switch into the manual position.

- Press the coin door Advance button. On system3 to system6,

the score displays should go blank. On system7, all the score displays

will light up with "0000000".

- Press the coin door Auto-up/Manual switch into the auto-up position.

- System3 to System6 only: Press the coin door Advance button.

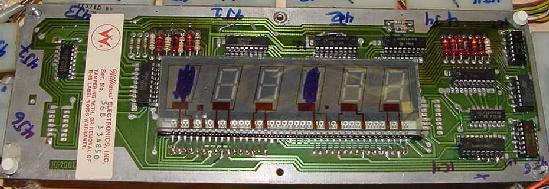

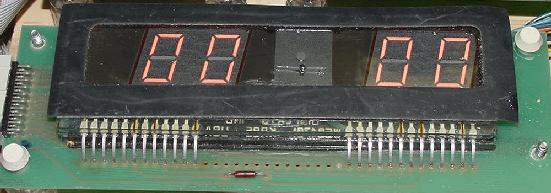

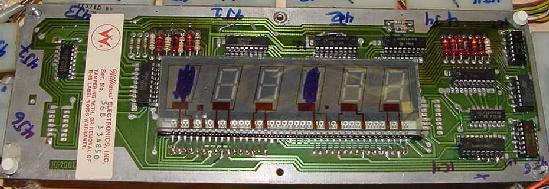

- The game should now go into the first test, which is

the SCORE DISPLAY test. All the score displays (including the credit/ball-in-play)

should cycle from "000000" to "999999". If a particular display

does not work or shows the wrong values, go to the

score display repair section.

- System 7 only: Press the Advance button again to pass over the

score display test. This will go

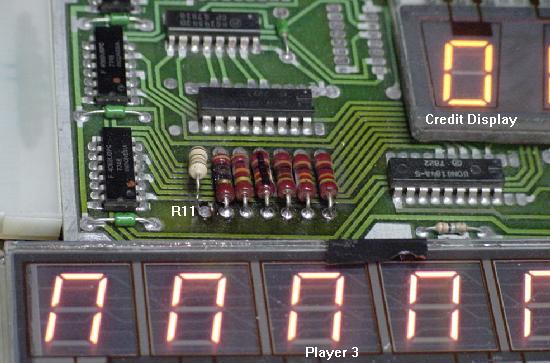

to test 00, as indicated in the credit score display, which is

the SOUND test. Each sound number will be displayed in the ball-in-play

window, and played by the sound board. If a sound is missing or there

is no sound, go to the

sound repair section.

- Press the Advance button again to pass over the previous test.

This will go to test 01,

as indicated in the credit score display, which

is the LAMP MATRIX test. All the CPU controlled lamps

will cycle on and off at once. If a number of lamps are not working

(and it's not burnt out bulbs), go to the

lamp matrix repair section for more details.

- Press the Advance button again to pass over the lamp test.

This will go to test 02,

as indicated in the credit score display, which

is the SOLENOID test, and each solenoid from 01 to 22 (as

indicated in the ball-in-play display) will be exercised.

Remember on system3 to system6, coils 9-13 are usually sound drivers.

System7 games will also test coil numbers 23,24,25

(25 is the flipper relay, but 23/24 are unused in

all system7 games). If a particular coil or group of coils does not work, go to the

coil repair section.

Note for the special solenoids (coils 17 to 22), be sure to

test these solenoids using the playfield trigger switches too.

Just because a special solenoids 17 to 22 work in diagnostics does *not* mean

they work in the game, as these coils have two distinct hardware

triggers.

- Press the Advance button again to pass over the solenoid test.

This will go to test 03,

as indicated in the credit score display, which

is the SWITCH MATRIX test.

On system3 to system6,

the ball-in-play display will show the last read (closed) switch number.

On system7 only, if there are multiple switches closed, the switch

numbers will alternate in the ball-in-play display.

If a switch or number

of switches do not work, go to the

switch matrix repair section.

- Press the Advance button again to pass over the switch matrix test.

This will go to test 04,

as indicated in the credit score display, which

is the AUDITS. The ball-in-play display will show the audit

number, and the player1 score display will show the audit value.

The Advance button can be pressed to move

from audit to audit. Check the game manual for a list of

audit numbers and what they represent.

To exit the diagnostics or audits, turn the game off and back on.

On system3 to system6 games, after accessing the last audit number,

pressing Advance will wrap the audits back to audit number 01. On

system7 games, after accessing the last audit number, pressing Advance

will put the game back into attract mode.

System3 (White Flipper ROM) Diagnostics.

On system3 (white flipper ROM) games, getting to the

diagnostics is a bit tricky (sometimes it will frustrate

me so much, I end up putting yellow or green flipper ROMs and an

appropriate Game ROM temporarily in the CPU board so I can easily get

to the diagnostics!)

Once you have done it a few times and understand

the timing, it's a lot easier.

Having good batteries in the CPU board with system3 white flipper ROMs

is also very helpful. No batteries and a system3 ROM CPU board acts strange

(compared to system4 to system7 games),

and is more difficult to get into diagnostics. With no batteries the

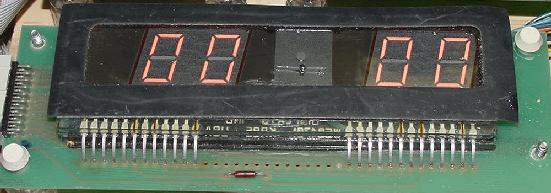

game will boot into audit mode (often "01 04" or "18 04" on the score ball/credit display,

and if the manual-down/auto-up switch is in the auto-up position,

it will auto-increment the first number pair). Also white flipper ROM

diagnostics run slower than yellow and newer flipper ROM diagnostics.

You will notice this especially in the solenoid and switch test

modes, as it seems the game is almost in slow motion in it's reactions,

compared to later games.

Here are the system3 white flipper ROM diagnostic instructions:

- With the game in attract (game over) mode,

set the coin door Auto-up/Manual-down switch to Manual-down.

- With the coin door open, press the Advance button once.

This should show audit #18 in the credit display

("18 04" in the credit/match displays).

- Press the Auto-up/Manual-down switch to Auto-Up.

The audits will now start auto-incrementing, counting up,

automatically showing the audits.

- Press the Advance button twice, with about 1/2 second of time

between the two button presses. Yea I know, this sounds very

precise, but it must be done this way! This is where the "timing" comes

in, and practice is the only real way to get this.

If done correctly, the score displays should now be blank.

If the two switch presses are done too fast or too slow,

the game will return to attract mode,

and you'll have to start over at step one above.

- Press Advance once again, and the game should now go into the first test, which is

the SCORE DISPLAY test. All the score displays (including the credit/ball-in-play)

should cycle from "000000" to "999999". If a particular display

does not work or shows the wrong values, go to the

score display repair section.

- Press the Advance button again to pass over the score display test.

This will go to test 01,

as indicated in the match (ball in play) display, which

is the LAMP MATRIX test. All the CPU controlled lamps

will cycle on and off at once. If a number of lamps are not working

(and it's not burnt out bulbs), go to the

lamp matrix repair section for more details.

- Press the Advance button again to pass over the lamp test.

This will go to test 02,

as indicated in the match/ball in play display, which

is the SOLENOID test, and each solenoid from 01 to 22 (as

indicated in the credit display) will be exercised.

Remember often system3 games coils 9-13 are sound drivers.

If a particular coil or group of coils does not work, go to the

coil repair section.

Note for the special solenoids (coils 17 to 22), be sure to

test these solenoids using the playfield trigger switches too.

Just because a special solenoids 17 to 22 work in diagnostics does *not* mean

they work in the game, as these coils have two distinct hardware

triggers.

- Press the Advance button again to pass over the solenoid test.

This will go to test 03,

as indicated in the match/ball in play display, which

is the SWITCH MATRIX test. The credit display will show the last read (closed)

switch. If there are multiple switches closed, the switch

numbers will *not* alternate in the credit display. If a switch or number

of switches do not work, go to the

switch matrix repair section.

- Press the Advance button again to pass over the switch matrix test.

This will go to test 04,

as indicated in the match/ball in play display, which

is the AUDITS. The credit display will show the audit

number, and the player1 score display will show the audit value.

The Advance button can be pressed to move

from audit to audit. Check the game manual for a list of

audit numbers and what they represent.

To exit the diagnostics or audits, turn the game off and back on.

On system3 to system6 games, after accessing the last audit number,

pressing Advance will wrap the audits back to audit number 01.

Pulse Lengths in Diagnostics.

The length of time a coil is "pulsed" in diagnostics may not be long

enough to make the device "dance". That is for example, in game mode, it takes

a fairly long pulse to reset a drop target bank. But in diagnostics,

usually shorter pulses are used. So if that drop target bank does not

reset in diagnostic mode, don't worry about! Wait until game play

and test the coil there before working on something that isn't really

broken.

Diagnostics Not Working.

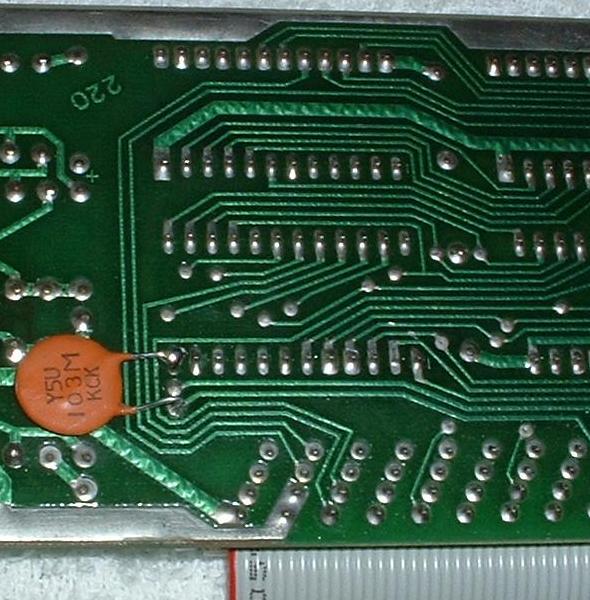

If a CPU board connector 1J4 is not attached, the coin door buttons

for diagnostics will not work. This connector is the second from

the left across the top edge of the CPU board. Cracked header pins

on this 1J4 connector can also cause problems. And if the adjustments/diagnostics

just keep rolling (even though the coin door switches are not shorted or

being pressed) after entering diagnostics, CPU chip IC5 (74ls02) could be bad.

3d. Before Turning the Game On: Random Lockups

& Resets: What Causes Them & Testing for Them.

Random lock-ups and resets includes the game shutting down during

play or attract mode, or it just goes crazy making random sounds and

scoring invisible points. Another commonly seen reset is if

both cabinet flipper buttons are pressed during game mode,

the game ends and goes into "attract" mode. If the backglass is

removed and this repeated, you will see the game is actually

rebooting (note the LEDs flash or on system7 the "0" code flashed

on the segmented LED).

These problems are usually caused by either one of three problems:

power supply ripple, weak bridge rectifier, connector failure, or a bad coil diode.

For example, if the game resets when pressing one or both flipper

buttons, then there may be a broken or missing diode on a flipper coil.

A broken diode allows the voltage to reverse back to the power supply.

This is caused by the collapse of the

coil's magnetic field (interestingly, a 30 volt coil will produce

a 60 volt back "spike"). This completely freaks out the power

supply, causing the game to reset. Replacing the coil's diode

usually fixes this problem.

Game Resets.

If the game resets when pressing one or both flipper

buttons, then there may be a broken or missing diode on a flipper coil.

A "reset" is classified as this:

If both cabinet flipper buttons are pressed during game mode,

the game ends and goes into "attract" mode. If the backglass is

removed and this repeated, you will see the game is actually

rebooting (note the LEDs flash or on system7 the "0" code flashed

on the segmented LED).

Check the flipper coil diodes first as it's the easiest thing to check. Gently tug

on the flipper coil's diode(s) to see if they are cracked or not

properly soldered to the coil's lugs. If no problems are seen with

the flipper diodes, next check the power supply filter capacitor

for AC ripple. With the game on put the DMM leads across the

power supply's large filter cap. Less than .200 volts AC should be seen on

system7 (or system9/11), and less than .300 volts AC on system3-6.

If more than that is seen, replace the filter cap. On System3-6 games with more

than two flippers, use a 15,000 MFD filter cap. On system3-6 games

with two flippers, a 10,000 MFD filter cap should work fine. On system7

(or system9/11) I recommend a 15,000 MFD filter cap.

Also on system7 (and system9 and system11) games, often the power supply's

5/12 volt bridge rectifier needs to be replaced.

I install a new 35 amp 200 volt bridge rectifier. Replacing

the bridge and the filter cap will usually

fix a flipper-envolked reset problem.

Game Lock-Ups: a Summary of What Could be Wrong.

At this point, all the circuit board updates and modifications

should have been performed. If the game boots, it is now time to

test for random resets and lock ups.

If a reset/lockup happens, it is usually related to the

following:

- Bad CPU/Driver 40 pin interboard connector.

- Bad CPU/Driver board chip sockets ("Scanbe").

- Bad board connectors and cracked solder header pin solder joints.

- Bad 1J2 CPU board power connector.

- Bad +5 volt filter capacitor.

- Bad bridge rectifier (system7).

- Missing/broken diodes on a coil(s).

- Problem with the switch matrix.

The first thing to notice is if the problem occurs only during game play, or

just while the game is in attract mode (in both circumstances).

The second thing to notice is does the game reset, or does it lock up

(a lock up is defined as

the two CPU board LEDs are on, or there's a "0" on the 7-digit System7 CPU board display).

If the game *resets* during play, this is usually a power related problem

(bad coil diode, bad +5 volt filter capacitor, or problem with the switch matrix).

See above for solutions to that.

If the game *locks-up* during play or in attract (game over) mode,

the problem is usually connector related.

Games that reset while in attract mode usually have

connector related problems or low line voltage (below 115 volts).

Testing for Resets.

To narrow this down to a intermittent connection (points 1,2,3,4 above),

or to a +5 volt filter cap, missing diode or switch problem, try the following.

With the game off, remove fuses F2 and F3 from the power supply

(solenoid and lamp matrix fuses).

Now turn the game on and go into self test. Put the

game in the "digits test" (which conveniently is the first self test),

so that the displays are cycling all the

different score display numbers. Now just walk away for a couple of hours or more

(letting this test run overnight works well).

Upon returning, if the score digits are not cycling, then the game

reset without any game play occuring. This means there is

an intermittent problem (points 1,2,3,4 above). If the game

is still in the digits test, then the reset problem is probably

a bad +5/12 volt filter capacitor, broken coil diode, or a switch matrix problem.

Bad 5/12 volt Filter Cap.

A bad +5/12 volt filter capacitor will really only show its ugly

head when the game is played. The coils turning on and off

forces the +5 vdc filter cap to work harder. If it's bad,

it should show pretty quickly in game play. Likewise for

bad coil diodes, and switch matrix problems (though often

switch matrix problems can be duplicated in the diagnostics

switch matrix test).

Missing or Broken Coil Diode.

A missing or broken coil diode (especially a missing diode

on any flipper coil) can really cause strange game behavior and resets.

For example, a missing/broken flipper coil diode can cause the

game to reset if one or both flipper buttons are pressed.

A broken diode on another type of coil can cause a reset just

when that device is used.

For example, a reader reported that the flippers caused the game to lock up

on his Firepower.

He went to the game's coil test, and noticed the middle

right multiball saucer solenoid was not firing. He replaced that coil's

diode (which fixed the saucer coil),

and the flippers no longer caused the game to lock up.

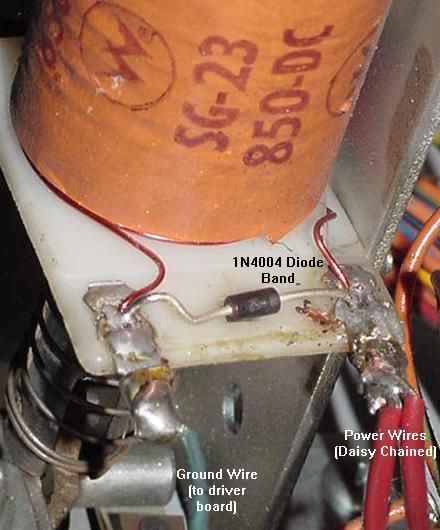

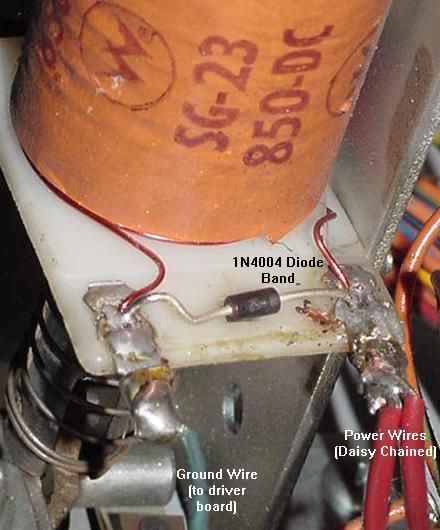

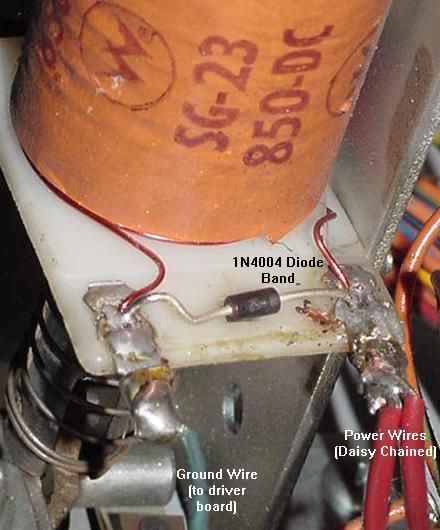

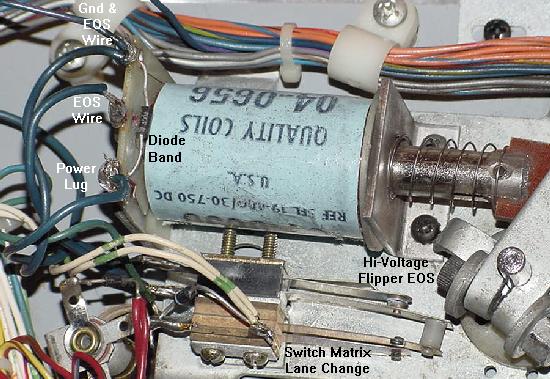

Be sure there is a 1N4004 on *every* coil. A good way to test

for a broken/cracked diode is to try grabbing the diode with

your thumb and forefinger, and giving it a gentle tug. Often

the body or lead of a diode can crack, and this will identify

it. If there's any doubt though, just replace that diode with

a new 1N4004 diode. They are inexpensive, and it's an easy

job. Just remember that the banded side of the diode goes

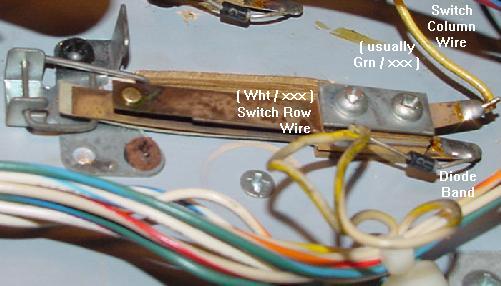

to the power lug/wire on the coil (the power wire is usually

the thicker wire, and is "daisy chained" from one coil to another).

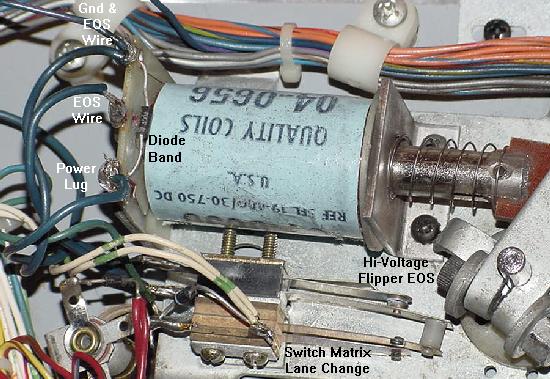

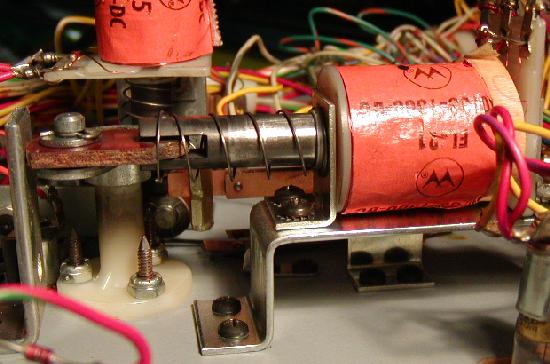

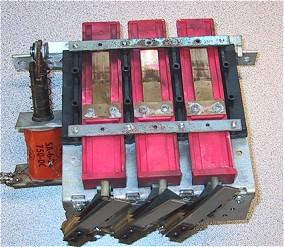

The 1N4004 coil diode mounted on a Firepower slingshot,

showing the proper orientation of the diode and power wires.

|

Diodes can be tested with a DMM, but frankly it's not

worth it, as one lead of the diode needs to be disconnected from

the coil for a good test. To go through the work of removing

one end of the diode, it's about as easy to just replace the

questionable diode instead. But here's how to test a coil diode:

- Turn the game off.

- Unsolder or cut one end of the diode from the coil.

- Use a DMM set to the diode function.

- Put the black DMM lead on the banded side of the diode.

- Put the red DMM lead on the NON-banded side of the diode.

- .4 to .6 volts should be seen.

- Reverse the DMM leads, and a null reading should be seen.

- If these values are not seen, replace the diode with a

new 1N4004 diode.

The Switch Matrix and Resets.

If there is a short in the switch matrix a bad diode on a playfield

switch, or a mis-wired playfield switch,

this can cause resets and strange game behavior too. For example,

column one of all system3 to system7 games have the tilt and slam tilt

switches. If another switch gets shorted in the same row or column

as a tilt switch, strange game behavior can occur during game play

as other switches are activiated in that row or column.

Summary.

The only way to fix the listed things above is *replacement*

of parts! New 40 pin connectors between the driver and CPU

boards, new chip sockets to replace the old "Scanbe" sockets,

new power connector at CPU board 1J2, and new

+5 volt filter capacitor.

And while the CPU and driver boards are out, might as

well resolder all the .156" male Molex connector pins on the

edges of the boards, as these often crack.

3e. When Things Don't Work: Non-Working or Locked-on

Coils/Flashlamps

Introduction.

In a working game,

the first thing to remember on all coils and flashlamps

is power is *alway* present at all coils/flashlamps. All these devices

are waiting for is the backbox driver board to complete the

their power circuit to ground, causing the coil or flashlamp to energize.

Essentially the driver board is a big computer controlled grounding

plane. Through the game ROM program, the CPU, and the PIAs (Peripheral

Interface Adaptors), the game can control

which driver board transistor can "sink" a ground, and hence complete

a particular coil's power path (causing the coil/flashlamp

to energize for a short period of time).

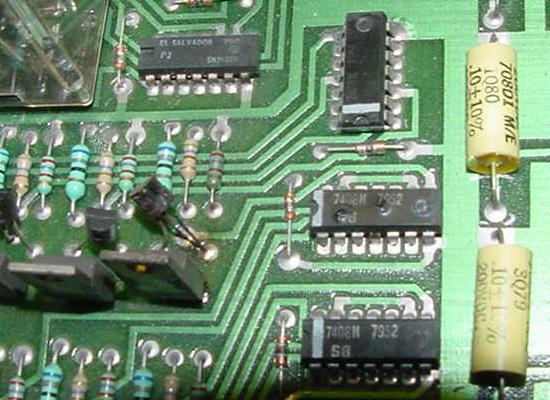

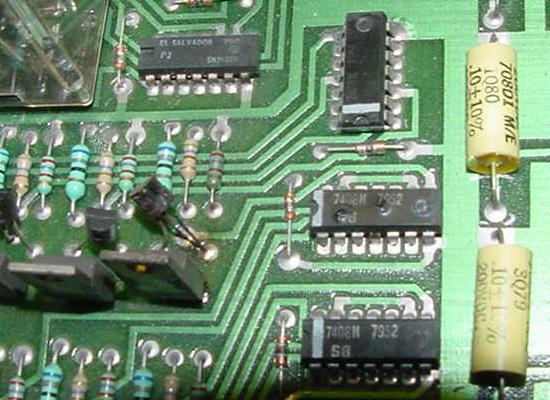

The way the driving logic works is as so: the CPU, which is

running the game ROM program, wants to energize a coil. It

tells the a PIA (Peripheral Interface Adaptor)

to turn on the appropriate coil.

This in turn drives a 7408/7402 chip, which then turns on a small

"pre-driver" 2N4401 transistor. So far this is all done with

"logic level" 5 volts. Then the pre-driver transistor turns on

a much bigger TIP120/TIP102 transistor. This final link in the

chain is what ultimately completes the coil's path to ground,

causing the 28 volt coil to energize momentarily.

A potential problem with this system is if ANY part in the

chain shorts, everything else down the chain turns on, and

a coil locks-on. Typically this is last link in the chain,

the TIP120/TIP102 driver transistor, becoming "shorted" internally

(because this device is in direct line with the 28 volt solenoid

voltage, where the other devices are "buffered" from this voltage).

But it could be

any of the other parts too! (the 2N4401 pre-driver transistor,

the 7408/7402 chip, or the PIA chip!) It could even be ALL these

devices short on!

So instead of

the CPU controlling the driver transistor (and hence

its associated coil/flashlamp), the coil/flashlamp becomes

lock-on (permanently energized), because the path to ground

is shorted inside one or many of the controlling devices.

So if a coil (or several coils) or flashlamps are locked-on,

the TIP120/TIP102 is at minimum is usually the cause.

But the big problem is if the TIP120/TIP102

driver transistor shorts, sometimes the "backlash" can ruin

the parts behind it (2N4401, 7408/7402, PIA) that control

the transistor.

All Coils Locked on - the Blanking Signal and Other Causes.

In Williams system3 to system7 games, there's another reason

a bunch of coils/flashlamps would be locked on. That would be

if the blanking signal is not high, allowing all the coils

to energize at power-on and stay energized. We really won't talk

too much about that condition

in this section, as that's really a failed CPU/Driver board issue

(and not a failed coil/transistor). See the

Dead CPU section for more info on that subject.

Note if only a one or a few coils are energizing at power on,

then there is probably a shorted driver board

transistors, and NOT a problem with the blanking signal.

The blanking signal is a "flag" from the CPU board to the driver

board. If the blanking signal is high (4 volts or greater), the

CPU board is saying to the driver board, "Hey! I'm working and ready!"

If the blanking signal does not go high, the driver board does not

"wake up", and often this means all the game's coils will energize!

A low blanking signal can signify there is a CPU board problem.

But there could also be a high CPU board blanking signal that

gets "lost" while going over the 40 pin interboard connector,

leading to the driver board!

The blanking circuit should go HIGH very soon after the machine is

powered-on (almost instantaneous). When the blanking signal is LOW,

it allows all the coils to energize automatically.

In general, the blanking circuit reading can be taken at pin

37 of the 40-pin inter-board connector (4th pin from the left),

and should be at least 4 volts. This is

where the blanking signal goes from the CPU to the driver board.

Aside from the blanking system, I have also seen other conditions where

all the coils energize at game power-on (this was a Williams Time Warp.) Of course you'll

hear a big "thud" as the coils all pull at power-on, until the power supply

solenoid fuse blows. It was a strange condition as even the

flipper relay would stay energized (flippers worked in game over mode),

and the sound board was making noise too (sound board inputs are controlled

by the driver board on system3-6 games.) A very strange occurance

indeed. In this situation the game did completely boot

(score displays showing high score, playfield lamps

"dancing" in attract mode.) So it was no surprize that pin37 of the interconnector

was high (signifying the blanking signal was good.) But what

caused this? Turns out the problem was a bad driver board

solenoid IC5 PIA 6821. Replacing this 40 pin chip fixed the problem.

I really was second guessing myself too, as using a DMM set to

diode function (red lead to ground) and testing each pin of

the PIA with the driver board removed did not show any issues

(everything tested .4 to .6). But obviously that's not

a great way to test a PIA chip (though it can show direct

shorts.)

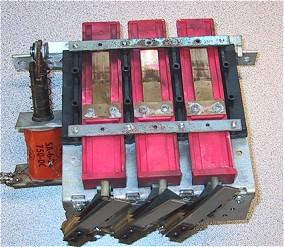

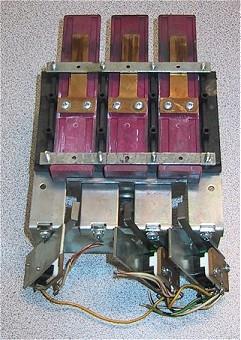

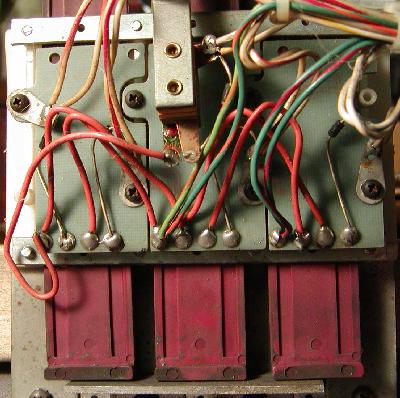

Solenoid Power Circuit.

The 28 volt solenoid circuit consists of a bridge rectifier

mounted on the backbox.

Like the lamp rectifier, its a 35amp, 400 volt bridge rectifier. After that,

the power goes to the power supply board, and thru a 47volt varistor

used to protect the coils from a voltage spike (if the voltage goes above 47 volts,

the MOV varistor shorts, which will blow the main solenoid fuse).

There is also a 100 mfd filter capacitor.

The driver board driver transistors are the most probable source of solenoid

problems. But an easy first test is to measure the voltage at connector

3J3 pins 6-9 on the power supply board,

which should show about 28 volts DC. If there is no voltage, check the solenoid

fuse F2. If there is a lower voltage, the backbox mounted bridge rectifier

has probably partially failed. If the voltage is higher than 28 volts, don't worry

about it (as long as it's not more than 47 volts!) The "unloaded" system should

measure higher than the "loaded" 28 volts DC.

Flipper Power Circuit and the Flipper Relay.

Next to the GI circuit, this is the simplest circuit in the game.

The only electronic part is the bridge rectifier that is shared with the

solenoid circuit (discussed above). Note the flippers do not use a filter

capacitor. On System3 and System4 games,

28 volts DC goes directly to the flippers from the backbox bridge rectifier,

with the flipper fuse located under the playfield. Starting with Flash (System6),

the flipper voltage is "passed through" the Power Supply board, with fuse F4

now protecting the flipper coil circuit, instead of a playfield mounted flipper

fuse.

Remember later system7 games (Firepower2 and later) have a separate 50 volt

power supply board for the 50 volt flippers. This upgraded flipper voltage

was increased from 28 to 50 volts to give the flippers a bit more snap.

But the rest of the coils in the game are still 28 volts.

If the flipper coils don't work or don't shut off after a games ends,

there may be something wrong with the driver board mounted Z1 flipper

relay (or the transistor and other components

that drive the flipper relay, and these part number are the same for all system3

to system7 games). This is kind of a last thing to check,

as flipper relay problems are not common. Test the 2N4401 transistor Q13 (positioned

right next to the relay) with the testing procedures described in the

Transistor Testing section of this guide.

Also the 7402 chip at IC8, which drives transistor Q13 could be bad.

There have even been reports of resistors R27 (4.7k 1/4 watt) and

R26 (10k 1/4 watt) being bad, in addition to diode D1 (1N4001).

Lastly test the flipper relay itself, as the relay does go bad

(the driver board will need to be removed to do this). A 9 volt

battery can be used on the relay's coil lugs (the two isolated

lugs from the other 12). Use the battery and

check if the relay

actually pulls its armature in and out (it should click nicely).

If a replacement relay is needed,

this relay is a 4PDT (4 pole double throw), 40 ohm, 6 volt relay,

and a suitable replacement can be found at Mouser.com, part #528-7810-1

(MagneCraft #W78CSX-1, $5.50).

Don't Forget the Grounding Strap.

In the backbox behind the backglass, there is a ground wire/strap which

attaches to a wing nut. This ground strap is very important, and

must be connected. On many system3 to system7 games, some features

of the game won't work (or won't work properly) if it's not attached to the

wing nut and the wing nut tightened.

Also later games from Firepower on had an

additional white-with-red trace grounding wire coming from the

playfield that needs to be cinched under the wing nut along with

the braided ground wire.

Remove Fuses F2 and F3 When Doing Intial Testing.

Be careful when testing an unknown game. At power-on, some coil may lock on

and constantly

energize. This will burn both the coil and its driver transistor. Until

the CPU is working properly, it is wise to remove coil and lamp fuses F2

and F3 from power supply board to minimize problems.

The Coin Door Coin Lockout Coil.

On the coin door, there is a small relay sized coil known

as the "coin lockout coil". When a system3 to system7 game

is powered on, this coin lockout coil should always be energized!

Yes that's right, the associated driver board transistor should

always allow this coil to be "on", when the game is powered on.

When the coin lockout coil is de-energized, the game will reject

money. This is done so if some (dumb) player inserts money into

a powered-off game, their money is returned to the coin return shoot.

Basically if the game is on, the coin lockout coil is energized. It is

even energized when the game is in diagnostic mode (on most, but not

all system3-system7 games). Note on some games, if the game is set to

"free play" through the adjustments, the coin lockout coil will

de-energize when the game is on.

Coin lockout coils were done away with during system11 I believe.

Williams needed the transistor for other more important chores,

like playfield devices.

Could the coin lockout coil be blowing the solenoid fuse? Yes!

Since this coil is on *a lot*, it gets hot with time. The winding's

wire bakes off its insulation, making adjacent windings short

to each other. This reduces the resistance of the coin lockout

coil from it's normal (about) 80 ohm resistance, to be lower.

As a coil's resistance becomes lower, it draws more current,

and becomes hotter. As it becomes hotter, it burns more winding

insulation. It's a endless cycle until the coin lockout coil

burns up. When a coil's resistance gets below about 2.5 ohms, it

essentially becomes a "dead short", and this will blow the

solenoid fuse.

This coil can be tested - Just put a DMM set to resistance on the

coil lugs (with it's driver board

connector J9 removed to isolate the coil) and check the resistance.

It should be greater than 50 ohms. Note the driver board

transistor that controls the coin lockout coils is Q45

(bottom row, furthest to the right).

A good way to test this transistor

is using the game's internal diagnostics and testing coil number 16

(the coin lockout coil will be energized during all of diagnostics

on most system3-7 games,

but when coil number 16 is tested, this coil should cycle on and off).

Another way to test transistor 45

is with a DMM set to the diode function, and the game turned off

(as described below).

Some good advice is to disconnect the coin door's coin lockout

coil. This can be done by cutting the ground wire (wire going to the driver board)

from the coin lockout coil. Then modify the coin door mech

so the coin lockout coil is not needed (that

is, if using the game with coins). This modification is very easy

(involves bending or removing the coil trigger bar).

The problem with the coin lockout coil is it is old, and usually

near death, often BUZZES loudly, consumes power (higher operating

costs), and it only causes problems. And frankly, in a home

environment, it's not needed! Even if operating the

game for money, I would disconnect it (it's only a problem waiting

to happen). If a player doesn't notice the game is off,

and puts money in, that's their problem!

CPU Controlled Solenoids.

CPU controlled solenoids are obviously controlled only by the CPU,

and the game ROM program that the CPU is running. CPU controlled coils also

have a "one shot" type operation, with a percise energize time.

By "one shot" I mean if their controlling trigger switch gets

stuck on, the coil fires one time (one shot), de-energizes, and

stays de-energized. So a stuck playfield switch only makes the

device non-operational, opposed to locking the device on and letting

it burn. CPU controlled solenoids are numbered one to 16 in

the solenoid diagnostic test and schematics.

The 16 CPU controlled solenoids are program activated by

PIA IC5 via a 7408 chip and two transistors (2N4401 pre-driver and a

TIP120/TIP102 driver).

The system3-7 CPU controlled solenoid schematic.

|

Special Solenoids.

Special solenoids on the other hand work differently than CPU controlled coils.

Special solenoids are used in pop bumpers and slingshot kickers, and since

they must act quickly, the CPU does not control them.

Closing of a special solenoid's playfield trigger switch

enables solenoid power directly through TTL (Transistor to Transistor)

chip logic and two transistor, without any processing by the CPU chip.

A second switch matrix switch is closed

when a special solenoid pulls in, which tells the CPU to score

the solenoid points (CPU controlled

solenoids do not need this second switch). Hence the special

solenoid trigger switches are not part of the switch matrix,

where the scoring switch is. Note

there are six special solenoids in the system3 to system7

driver board.

At the time,

it was felt that the clock speed of the CPU was not fast enough

to give quick acting pop bumpers and slingshot kickers, as the CPU was doing

other things like monitoring

the switch matrix and running the lamp matrix and score displays.

Note though two games, Time Warp and Stellar Wars, used five pop bumpers and

two slingshot kicker. Since there were only six special solenoids, something had

to give on these two games. In Stellar Wars, the lower right pop bumper was

a CPU controlled solenoid. On Time Warp both slingshot kickers

where CPU controlled solenoids.

But the story doesn't end there with Special solenoids. The

control of special solenoids on all system3 to system7 games

is directly through playfield control via the playfield trigger

switches. But interestingly, special solenoid can also be

controlled by the CPU too. This can be seen when running

the internal game diagnostics, and the game turns the special

solenoids on and off in the coil test. Because of these "dual trigger"

(two ways to turn on) functionality of the special solenoids,

these can be more problematic than the other 16 "CPU controlled"

coils on the game.

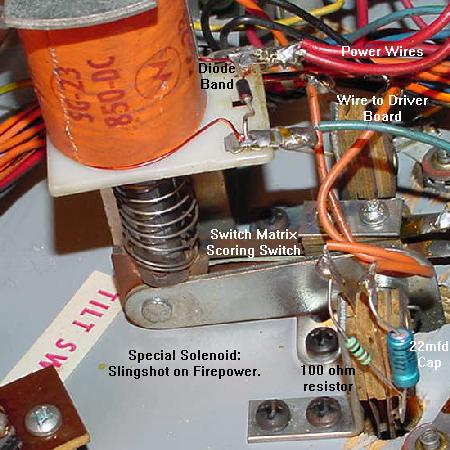

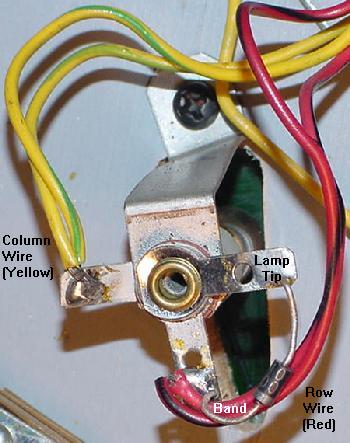

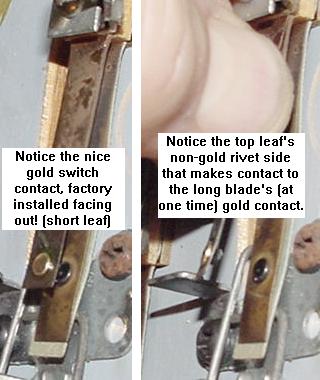

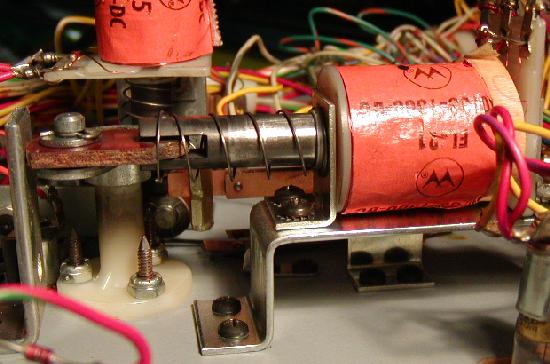

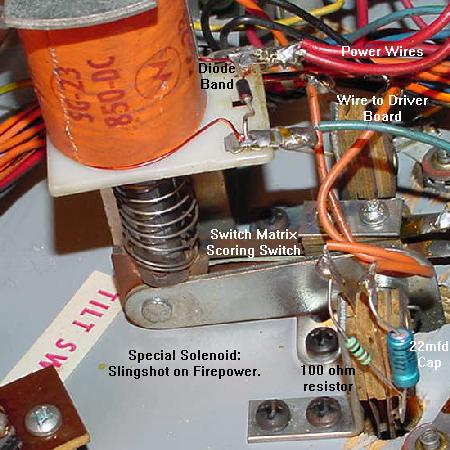

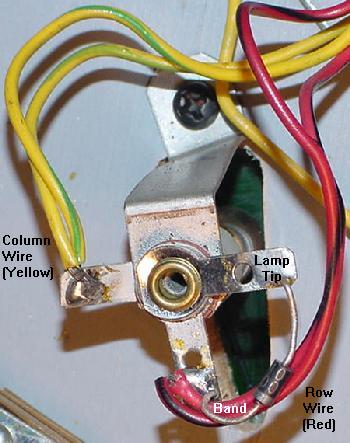

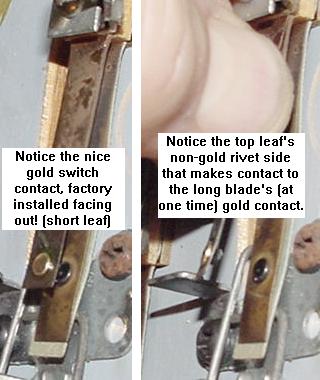

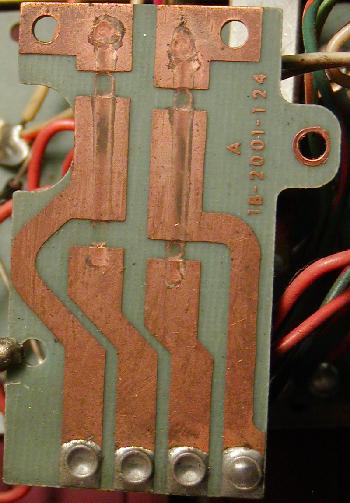

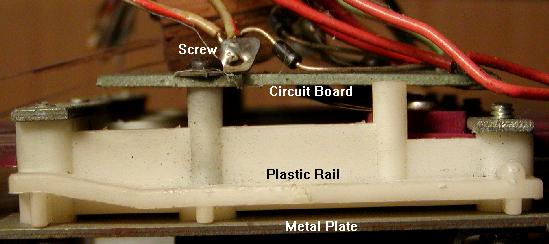

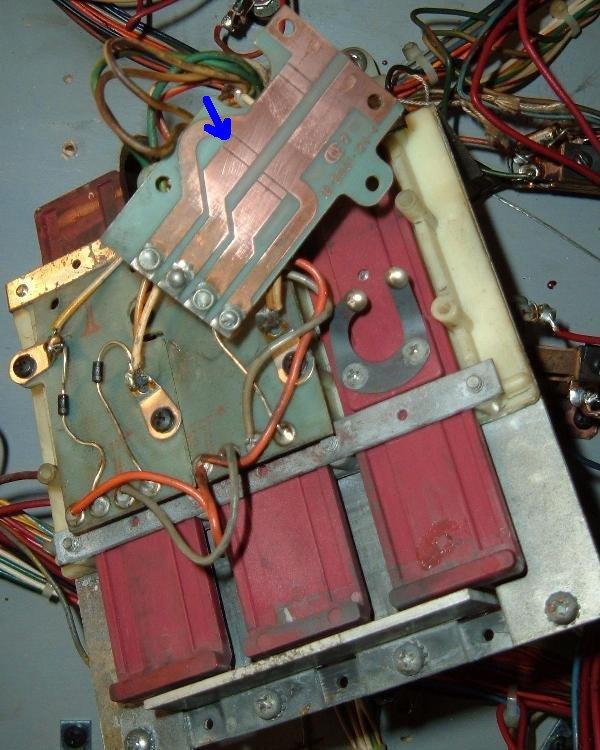

A special solenoid slingshot kicker on a Firepower. Note even this

coil uses a 1N4004 diode (with the banded end connected to the

power wire). In addition the playfield activition trigger switch

has a 22 mfd polarized cap and a 100 ohm resistor in series.

|

Special solenoids use a 7408 chip, a 7402 chip, and two transistors

(2N4401 pre-driver and a TIP120/TIP102 driver).

This is one more TTL circuit than the CPU controlled coils use.

A special solenoid operates if the playfield switch (through connector 2j13)

pulls one 7408 input low.

The other 7408 input can be pulled low by the CPU via a PIA (and this is what

is done in the diagnostic solenoid test). Then this goes to a 7402,

and then to the 2n4401, and finally to the TIP120 that sinks the coil's ground

(turning the coil 'on'.) So a special solenoid could work

in diagnostic test but not work in game mode (or vice versa). This confuses

a lot of people because the diagnostics show a coil a "working", yet when

playing the game the same coil does not respond.

In addition, right when a game is started, a special solenoid can

'lock on'. This is often due to a playfield switch being stuck closed.

But it can also be a problem with the 7408 or 7402 chip(s). If removing

driver board connector 2j13 (upper left corner) unlocks a stuck-on coil during game play,

then the problem is on the playfield. If the coil stays locked on

during game play with 2j13 removed, the problem is on the driver board

with either the 7408 or 7402 chip(s).

Also the the special solenoid playfield switch trigger has a 100 ohm

1/2 watt resistor and a 22 mfd 100 volt electroylic capacitor (the positive

lead connected to the resistor) in parallel to the switch. This is different

than CPU controlled coils that use a switch matrix switch to turn them on (switch

matrix switches only have a 1N4004 diode on the switch).

Again the thing about special solenoids that is really freaky is this: the diagnostics

can show the special solenoids as working, but in game play they may not

work! The opposite is also true; a special solenoid could work in the game,

but not in diagnostics. This happens because there are two different and

distinct triggers for the special solenoids. That is, playfield trigger

for the special solenoids uses different hardware logic then the

diagnostic trigger for special solenoids. This can be very confusing.

The logic flow for the special solenoids works like this:

the PIA IC5 and the playfield trigger switch feed to the same 7408 chip (IC6/IC7).

(Note the playfield trigger switch goes first thru a pullup 4.7k resistor (R1-R6)

which sometimes go open or out of spec causing problems.)

The 7808 is an 'OR' TTL chip, meaning if either of the switch input are triggered (playfield or PIA),

the TTL output turns-on the special solenoid circuit engerizing the coil.

The OR'ed 7808 trigger signal then goes to a 7402 chip (IC8/IC9), which goes to a

2N4401 pre-driver transistor, and finally to a TIP120 or TIP102

driver transistor (which ultimately sinks the ground and

fires the coil). So if a special solenoid only works in

game mode and not diagnostics, the problem has to be the 7408 chip or the PIA chip IC5.

If the special solenoid only works in diagnostic mode and not game mode, the

problem has to be the pullup 4.7k resistor (R1-R6), the 7408 chip,

or the playfield switch (and associated cap/resistor on the switch) or connector for the playfield switch.

If a special solenoid works with one trigger but not the other,

the 7402 and everything connecting after it (pre-driver, driver transistors, coil, etc.) are fine.

The system3-7 Special Solenoid schematic. Note the dual

inputs: either the playfield trigger switch, or the PIA.

|

To confuse things even more, the Special solenoids have yet another switch involved.

This is the scoring switch, which is part of the switch matrix (unlike the special solenoid

trigger switch). So each pop bumper and slingshot have a second physical switch mounted on the

playfield device. This switch closes as the coil energizes. This switch matrix switch in turns

tells the CPU to score the device (but does *not* tell the CPU to fire the coil).

So if there's a pop bumper or slingshot that works fine (energizes),

but does not score, often it's because this secondary switch matrix switch is mis-adjusted

or broken.

Slingshots that Barely Fire - the Slingshot Resistor and Cap.

A reader reports having a Flash pinball where the slingshots act strange.

If the pinball hits the slingshot rubber (or it is actuated manually),

it barely fires and there is a small kick. But if both sling rubbers switches are

manually touched together it works fine.

The solutions was to check the 22 mfd 25V cap and 100 ohm resistor in series (black

wire to - side of cap, + side of cap to resistor, resistor to other

side of switch) mounted on the slingshot switches.

These make the slings fire quicker and faster. In this the resistor was broken

on one side, and the capacitor was broken on the other side.

Replaced all the bad parts and it works fine now.

Special Solenoids that work in the Game, but Don't in Diagnostics.

The special solenoids work fine

while playing the game, but don't in the diagnostics. Should anyone

really care? After all, the only use for the CPU control of the special

solenoids is in the diagnostics. But I guess that's up to you to

decide whether it should be

fixed (after all, if the game plays, who cares?), but I'll try and explain

why this could happen.

In diagnostics, the special solenoids are controlled by the CPU via

PIA chips. Sounds simple enough, that's how the other 16 CPU controlled

coils work. But it's not that simple, because unlike the other 16 CPU

controlled coils which are controlled by PIA IC5 on the driver board,

the special solenoids use *four* PIAs for their CPU control!

Here's a logic chart:

Spec

Sol# |

Controlling

PIA |

PIA's Normal

Function |

PF Switch

Connector |

7408

In/Out |

7402

In/Out |

Pre-Drive

2N4401 |

Drive

TIP120/TIP102 |

| 1/17 |

ST1

IC10 pin 19 |

Lamp Matrix

(driver board) |

2J13 pin 5 |

IC6 pin 1/3 |

IC9 pin 2/1 |

Q1 |

Q2 |

| 2/18 |

ST2

IC10 pin 39 |

Lamp Matrix

(driver board) |

2J13 pin 4 |

IC6 pin 10/8 |

IC8 pin 12/13 |

Q3 |

Q4 |

| 3/19 |

ST3

IC11 pin 19 |

Switch Matrix

(driver board) |

2J13 pin 2 |

IC6 pin 13/11 |

IC8 pin 5/4 |

Q5 |

Q6 |

| 4/20 |

ST4

IC11 pin 39 |

Switch Matrix

(driver board) |

2J13 pin 4 |

IC6 pin 4/6 |

IC8 pin 9/10 |

Q7 |

Q8 |

| 5/21 |

ST5

IC5 pin 39 |

Solenoids

(driver board) |

2J13 pin 8 |

IC7 pin 13/11 |

IC9 pin 5/4 |

Q9 |

Q10 |

| 6/22 |

ST

IC18 pin 19 |

Score Displays

(CPU board) |

2J13 pin 9 |

IC7 pin 10/8 |

IC9 pin 12/13 |

Q11 |

Q12 |

Note one of the special solenoid controlling PIAs is on the CPU board,

not the driver board! (Better check that 40 pin interboard connector.)

So if the solenoid IC5 PIA was replaced thinking it would take care

of the special solenoids in diagnostics, chances are 5 out of 6 that the problem

will *not* be fixed! (Usually it's the 7408 chip anyway.)

And the special solenoids are not controlled by the PIA's "normal" ports. Instead

they use CA2 and CB2, which are two specialized ports on the PIA, at pins 19 and 39.

Leon's test chip does test pins 19 and 39 of all the PIAs, but unfortunately

the pulses are usually not as clear as testing the "normal" port at pins 2-17 of the PIAs.

Locked On Special Solenoids- The Trigger Switch, Cap, Resistor.

The bad thing about special solenoids is they are NOT a "one

shot" type device. If a special solenoid playfield trigger switch

gets permanently closed, it's associated coil "locks on", and stays

energized. And it will stay energized until either a fuse blows,

or the coil burns (and in the process burns up the coil's driver board

transistor). It is actually quite common for even a momentarily

locked on special solenoid to burn out its associated driver

transistor, and even the 74xx chips and PIA (this seems

to be a big problem with locked on pop bumpers).

It was strange that Williams choose to *not* make the

special solenoids "one shot", as even Gottlieb did on their non-CPU controlled

"one shot" pop bumper driver boards. Eventually Williams did make

all coils CPU controlled (with System11A), making everything "one shot".

So the moral of this story is to *always* check the special solenoid

trigger switch on the playfield. Also be sure to check the 22mfd 100 volt

capacitor and 100 ohm resistor that are wired in parallel to the switch

(and of course the coil's 1N4004 diode). The resistor can short closed,

essentially causing the playfield switch to be locked on. Same thing

for the capacitor, which can also short internally causing its special

solenoid to lock on. Note the resistor and capacitor can be removed, and

the system will still work (the easiest way to do this is to just

cut either lead of the resistor from its solder lug).

This is a good first step if a special solenoid

is locked on, as it removes another potential problem from the system.

But remember if the playfield switch is stuck on or the resistor/capacitor

is shorted, this could be the whole problem, and what

ultimately caused the "domino affect" of ruining the driver board parts,

the coil, etc. Also remember if the resistor and/or capacitor is cut

for test, they should be replaced or re-attached.

These were added to cause the special solenoid circuit to be

"on" for a brief period of time after the special solenoid switch opens

back up, in order to make the pop bumper "pop" better. It sort of fools

the driver board into thinking the switch is actually staying closed longer

than it really does, making the slingshot or pop bumper kick

a bit harder. Sometimes sluggish pop bumpers or slingshots can be

caused by its associated playfield switch's resitor or capacitor going open.

A pop bumper drawing showing the special

solenoid Trigger switch (not in the switch

matrix), and the scoring switch (which is in

the switch matrix).Pic by Norbert Snicer.

|

Also remember the special solenoid trigger switch is *not* part of

the switch matrix. So the game's switch matrix diagnostics can *not*

be used to test the playfield special solenoid trigger switch.

Testing Coils and Transistors

(Non-Working and Locked On).

There is a whole section about testing driver board transistor in the

Checking Transistors section of this document.

But outside of this, some other tests can also be used.

If unsure about a coil and whether it works, try these simple

tests, with the solenoid fuse F2 installed.

Remember, if a coil is locked on, check if it is a Special

Solenoid (pop bumpers and slingshots). The special solenoids

will "lock on" if their corresponding playfield activiation

switch is stuck on or shorted. So a locked on special solenoid

could be as simple as a permanently closed solenoid playfield switch.

Testing for Overall Solenoid Power.

If the coil does not fire, there may be

no 28 volts from the power supply. For this test,

the solenoid fuse F2 will need to be installed.

Using a DMM set to DC volts, do the following:

- Put the DMM black lead on the power supply ground connector 3J4 pin 1.

- Put the DMM red lead on power supply board connector 3J3 pins6-9.

- Turn the game on.

- There should be 28 to 47 volts DC.

If there is no voltage, check solenoid fuse F2. If this fuse

keeps blowing at power on, the backbox mounted 6BR2

solenoid bridge rectifier has probably shorted. If no voltage

or low voltage, this could also be the solenoid bridge

rectifier.

Testing for Good Coil Ohms.

If a coil has been over-heated (locked-on) previously, the coil

windings can get hot enough to burn their painted enamel

insulation. If this happens, the windings can short, causing

the overall resistance of a coil to be too low (essentially

making the coil a "short"). This can then

stress the driver transistor, eventually blowing it.

To check a coil for this problem, put a DMM on the low ohm

setting, and put each DMM lead on each lug of the coil. It

should read 3 to 150 ohms. If it is any lower than about 2.5 ohms,

the coil probably has an internal short and should be replaced.

Another indication that a coil has been heat stressed is if

its internal nylon sleeve can be removed from the coil. If this

coil sleeve can not be easily removed, chances are good the coil

has gotten hot enough to expand, and the coil should be replaced.

Remember when replacing a coil, the thicker POWER wire(s) go to the

coil lug with the banded side of the diode attached. The thinner

ground wire (which goes to the driver board) goes to the coil lug

with the non-banded side of the diode attached.

Testing for Power at a Coil/Flashlamp.

If the coil does not fire, there may be

no power at that coil or flashlamp.

For this test, solenoid fuse F2 will need to be

installed. Using a DMM set to DC volts, do the following:

- Lift the playfield up on the game.

- Turn the game on and let it go into attract mode.

- Put the DMM black lead on ground (the metal side rail).

- Put the DMM red lead on EITHER coil lug or flashlamp lug.

- Either lug should show 28 volts (for either a coil or flashlamp, as flashlamp

power is the same 28 volt power source).

If only one lug shows voltage, the coil or flashlamp is bad (it has

a broken winding). If

neither lug shows voltage, check "upstream" and see if

the daisy-chained thicker power wire broke off another coil/flashlamp

in the chain.

Testing the Coil/flashlamp.

If a coil or flashlamp is not firing, and

with power at the coil, this test will check if the coil or flashlamp

is capable of firing. For this test, solenoid fuse F2 will need to be

installed.

- Lift the playfield up on the game.

- Turn the game on and let it go into attract mode.

- Using an alligator test lead, attach one end to ground (the game's

metal side rail).

- Momentarily touch the other end of the alligator test lead to

the GROUND coil or flashlamp lug. The ground coil lug is the lug

with the non-banded side of the 1N4004 diode attached

(all coils should have a 1N4004 diode!), and the thinner wire attached.

The ground lug on a flashlamp is the lug that goes to the

resistors (usually the tip of the flashlamp socket).

The coil or flashlamp should fire. If the power lug is accidently

touched with the alligator clip, the solenoid fuse will probably

blow, and the game will probably reboot. If this happens, replace

the fuse and try again (touching the correct coil/flashlamp lug!)

IMPORTANT: While doing this, note the 1N4004 diode on the

coil. Make sure it is in good shape, not cracked or damaged, and

is connected to the coil lugs. More info on this diode is below.

Note there is no diode used on flashlamps.

Testing the Wiring from the Driver Board to the Coil/flashlamp.

For a non-working coil/flashlamp,

now it is verified there is power at the device, and the coil/flashlamp

can actually fire. It's time to see if the wiring from the

coil's non-banded diode lug (or from the flashlamp's resistor

board) goes uninterupted to the driver board.

- Check the schematics or operator's manual and figure out

which TIP120/TIP102 transistor number goes to the coil/flashlamp in question.

Or if schematics are not available, find the non-power wire color at the device.

Then go to the driver board and find that same wire color

at the connectors on the left edge of the driver board. Using a DMM set to continuity, put

one DMM lead on that driver board connector pin and touch the other DMM lead to all the metal tabs

of the driver board left-side TIP120 transistors. This will identify which transistor drives the questionable

device.

- With the game on and in attract mode,

use an alligator test lead, and connect one end to ground in the backbox.

- Using the other end of the alligator test lead, momentarily

touch the metal tab on the coil/flashlamp's transistor.

This should fire the coil/flashlamp in question.

Do this should fire the coil/flashlamp. If it does, the wiring from the driver board

to the coil is OK. If it does not fire, chances are good there is

a bad backbox/cabinet connector (common as the male connector header pin's solder joints

often crack where soldered to the driver board), or the wire is cut somewhere between

the backbox and the coil. If the problem is a non-working flashlamp, make sure to check

the under-playfield resistors for that flashlamp. Because the 12 volt flashlamp is run

at 28 volt solenoid voltage, there are two resistors used as additonal resistive "load"

so the 12 volt flasher doesn't burn out at 28 volts (one resistor is a "keep alive", the

other is used when the lamp is "fired"). If the "fired" resistor goes open, the flash

lamp will never work.

Everything Checks Out So Far, But the Coil/Flashlamp Still Doesn't Work.

Remember, if a coil is locked on, check if it is a Special

Solenoid (pop bumpers and slingshots). The special solenoids

will "lock on" if their corresponding playfield activiation

switch is stuck on or shorted. So a locked on special solenoid

could be as simple as a permanently closed solenoid playfield switch.

At this point, there is a driver board issue. Power is at the device,

and the wiring gets to the driver board, but the coil or flashlamp will

still not fire (or is locked on). This is a good indication

either the driver transistor has failed, or it's driving

7408 chip has failed, or even the driver board solenoid PIA at IC5

has failed.

Check the Driver Board Male Header Pin Solder Joints.

If the driver board is removed, it is really a good idea at this point to

re-solder the header pin connectors on the Driver board (obviously the

driver board needs to be removed for this work.) Heat

the joints with a soldering iron until the solder melts, and add some new solder.

Sometimes it's difficult to get the solder to stick to encompass the head pin "butts".

So an even better method (though more involved) is to remove the old solder

using a desoldering tool, and then resoldering the connector pin with new solder.

This is a good idea because the old solder often does not stick well to the

connector pins "butts".

But attempting to diagnose problems without first doing this is often a waste of time,

because the driver board flexs as it is removed from the 40 pin interboard connector

or as connectors are removed/attached.

This flexing causes cracks in the male header pin solder joints, causing intermittent

or non-working connections.

Testing the Driver Board Transistors.

This should be done for a non-working or locked on coil or flashlamp.

The driver board does not need to be removed for this test, but it does make the job easier.

This procedure is listed in the

Checking Transistors section of this document too.

All transistors are tested using the diode function of a DMM

(Digital Multi Meter).

Important Note: Testing transistors (or chips) using the methods below

does not give 100% proof that a transistor is good or bad.

It's probably about 95% accurate, but it is not 100% accurate

(especially if the transistor is mounted in a circuit board).

I will say this - if a transistor tests as "bad", then it's bad (or the TTL

chip that feeds it is bad).

But if the transistor tests as "good" that does not necessarily mean

the transistor is good.

If the driving TIP120 transistor is bad, be sure to replace it with

a more robust TIP102 transistor. Also make sure to replace the

pre-driver 2N4401 transistor that accompanies the TIP120/TIP102.

At this point, it is best to test the driving 7408/7402

chip. It only takes a moment, and saves a lot of work if this

chip is damaged. Also a bad 7408/7402 can cause a driving transistor

to test as "bad".

Testing the 7408/7402 Chips and Solenoid PIA.

At this point, the TIP120/TIP102 and pre-driver 2N4401 are tested/replaced,

but the coil/flashlamp is still locked on.

Now it's time to test the 7408/7402 driver chips.

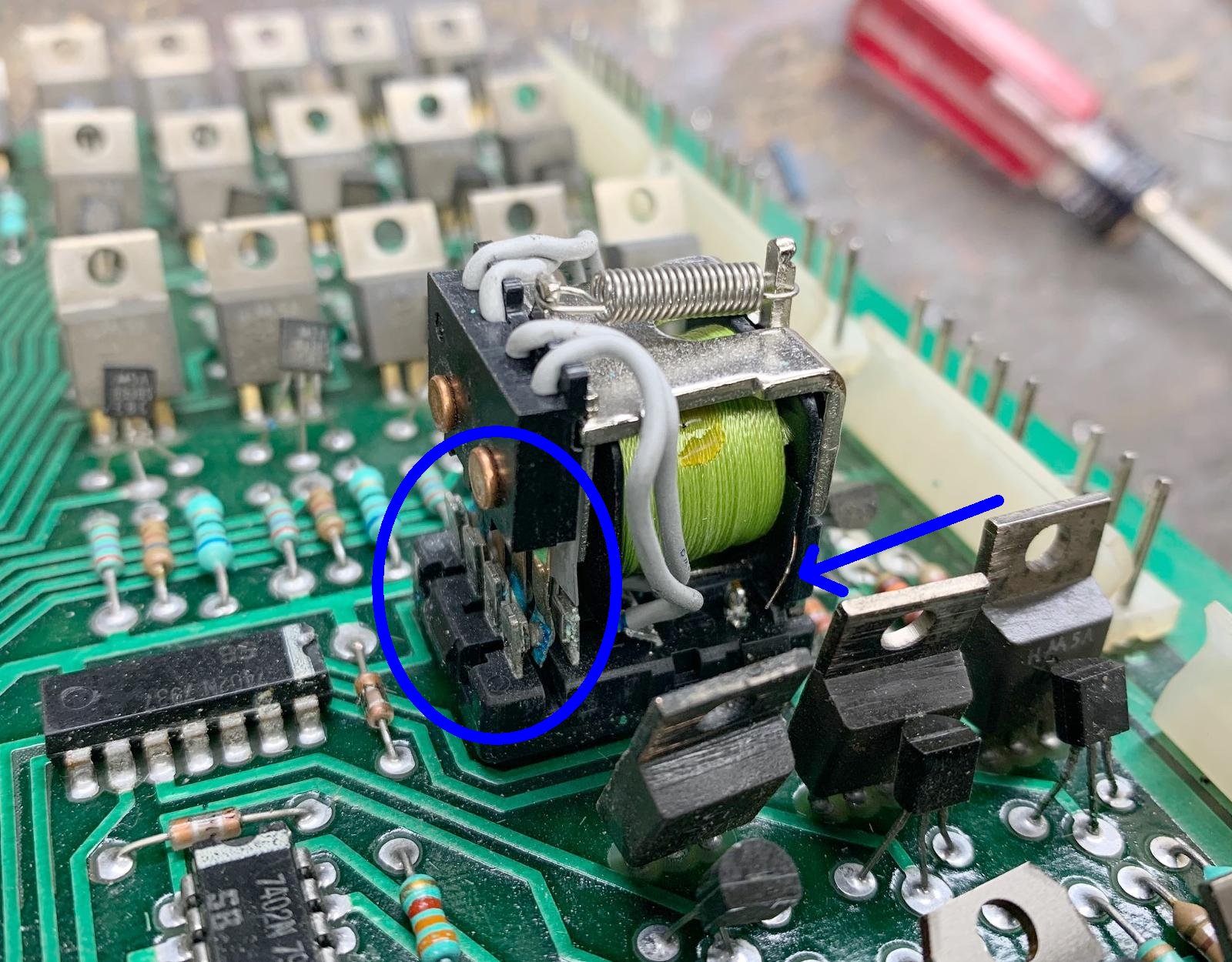

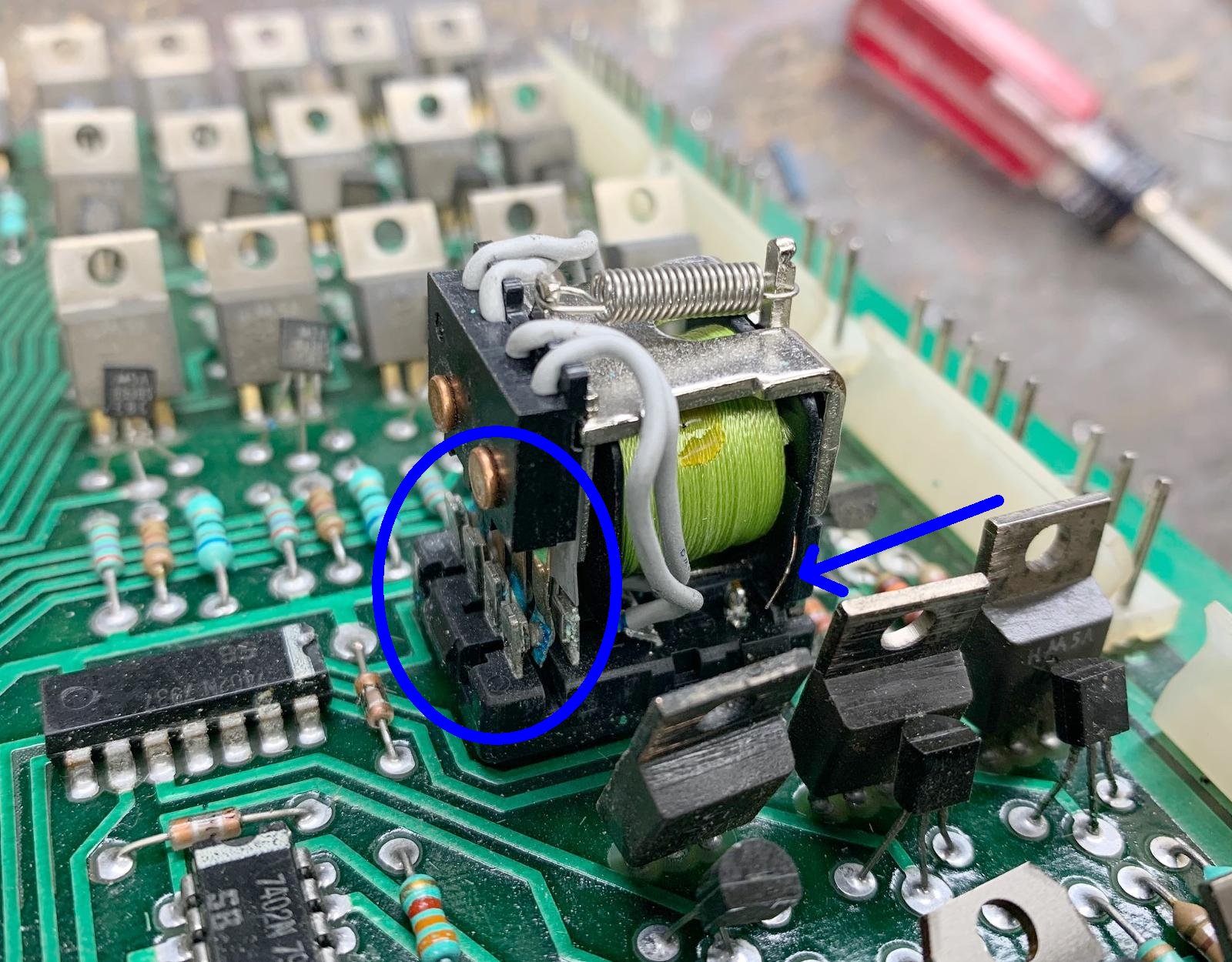

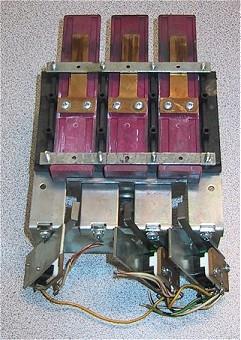

No need to test this 7408 chip! The 7408 in the middle is physically

bubbled up and can easily be seen as "bad". It can be counted on that

the 2N4401 pre-driver and TIP120/TIP102 driver transistors are blown too!

Just hope the IC5 solenoid PIA chip survived.

|

These chips can also be tested with a DMM set to the diode function and the

game off. For a 7408, put the red lead on ground (pin 7), and

put the black lead on pins 1,2,3, 4,5,6, 8,9,10, 11,12,13. A reading of of .4

to .6 should be seen for each pin (a reading lower than .2 is a big sign of a

bad chip).

Likewise a 7402 (used for special solenoids)

can be tested in the same manner. With the

game off. For a 7402, put the red lead on ground (pin 7), and

put the black lead on pins 1,2,3, 4,5,6, 8,9,10, 11,12,13. A reading of of .4

to .6 should be seen for each pin (a reading lower than .2 is a big sign of a

bad chip).

Remember though, testing TTL chip mounted in a circuit board

using a DMM's diode test can give false readings.

If the chip is socketed, it's better to use the DMM diode test

with the chip removed from the circuit.

An even better test (with the board powered on) is

to use a logic probe and to compare similar TTL chips.

That is, compare two (or more) similar 7408 or 7402 TTL chips which both control

solenoids (see the schematics).

TIP Transistor & TTL Checks Good, but Coil Locked On - Now What?

In the case of all coil *except* the special solenoids,

the only thing left is the PIA IC5. Luckily in the case of CPU controlled coils this is easy

to test. Have the solenoid power fuse removed. Using a logic probe, the

PIA IC5 outputs can be checked. With the game in attract mode,

all coil outputs from the PIA IC5 should be LOW (except for

the coindoor lockout coil), meaning the coil is NOT energized.

If the PIA outputs are missing or high, the associated coil will be locked on

(remember the coindoor lockout coil will be ON, unless the game is at maximum allowed credits).

The TTL 7408 is a two input, one output AND gate.

This means BOTH input signals must be HIGH for the AND gate to be completed,

making the output AND gate signal HIGH (and energizing the coil). If the game is successfully

booted, the Blanking signal is already high, so one of the AND inputs is high. Now

the 7408 is waiting for the PIA to make the other input AND signal momentarily high

to fire the associated coil.

In the chart below the first listed TTL is the AND gate output.

The next pin number (after the ":") is the AND input from the PIA.

The last TTL pin number is the blanking signal (which should be high in a booted game).

The output TTL pin (first listed TTL pin) should be low with the game in attract mode. If the

TTL input pin coming from the PIA is low, the blanking input TTL pin is high, but

the output TTL pin is high or missing, then the TTL 7408 chip is bad.

Below is a chart of the IC5 PIA and TTL outputs which should

be checked with the logic probe for a "low" signal (game powered on and in attract mode).

The system3-7 CPU controlled solenoid schematic (PIA, AND gate, transistors).

|

| Coil# | Connector | TIP 120 | 2n4401 | TTL (output, in PIA, in Blank) | PIA Output (low) |

| Coil 1 | J11 pin 4 | Q15 | Q14 | IC1 pin 8:10,9 | IC5 pin 2 |

| Coil 2 | J11 pin 5 | Q17 | Q16 | IC1 pin 11:12,13 | IC5 pin 3 |

| Coil 3 | J11 pin 7 | Q17 | Q16 | IC1 pin 6:4,5 | IC5 pin 4 |

| Coil 4 | J11 pin 8 | Q21 | Q20 | IC1 pin 3:1,2 | IC5 pin 5 |

| Coil 5 | J11 pin 9 | Q23 | Q22 | IC2 pin 8:10,9 | IC5 pin 6 |

| Coil 6 | J11 pin 3 | Q25 | Q24 | IC2 pin 11:12,13 | IC5 pin 7 |

| Coil 7 | J11 pin 2 | Q27 | Q26 | IC2 pin 6:4,5 | IC5 pin 8 |

| Coil 8 | J11 pin 1 | Q29 | Q28 | IC2 pin 3:1,2 | IC5 pin 9 |

| Coil 9 | J9 pin 9 | Q31 | Q30 | IC3 pin 8:10,9 | IC5 pin 10 |

| Coil 10 | J9 pin 7 | Q33 | Q32 | IC3 pin 11:12,13 | IC5 pin 11 |

| Coil 11 | J9 pin 1 | Q35 | Q34 | IC3 pin 6:4,5 | IC5 pin 12 |

| Coil 12 | J9 pin 2 | Q37 | Q36 | IC3 pin 3:1,2 | IC5 pin 13 |

| Coil 13 | J9 pin 3 | Q39 | Q38 | IC4 pin 8:10,9 | IC5 pin 14 |

| Coil 14 | J9 pin 4 | Q41 | Q40 | IC4 pin 11:12,13 | IC5 pin 15 |

| Coil 15 | J9 pin 5 | Q43 | Q42 | IC4 pin 6:4,5 | IC5 pin 16 |

| Lockout | J9 pin 6 | Q45 | Q44 | IC4 pin 3:1,2 | IC5 pin 17* |

*Unless game is at maximum allowed credits, the coin door lockout

PIA output will be high.

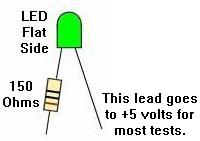

Leon Test EPROM could also be used for this test, but frankly I find that not necessary.

It's just easier to be running the game code in attract mode and testing the outputs

with a logic probe. But the Leon test chip procedure

is fully described in the Dead/CPU driver board sub-section,

CPU board is working, Install the Driver board.

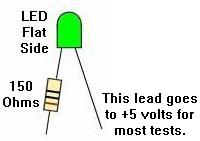

This shows how to test the PIA using a "tester LED" and

Leon's test chip.

FlashLamp Problems.

Flashlamps are controlled as solenoids, and are wired in series

(if there is more than one flashlamp fired by a single driving transistor).

The flashlamps are "doubled up" and wired in series so that

the 28 volt solenoid voltage can be used on the 14 volt flasher bulbs

(two times 14 equals 28 volts). But the problem with this is

if one flashlamp burns out, the other flashlamp will not work!

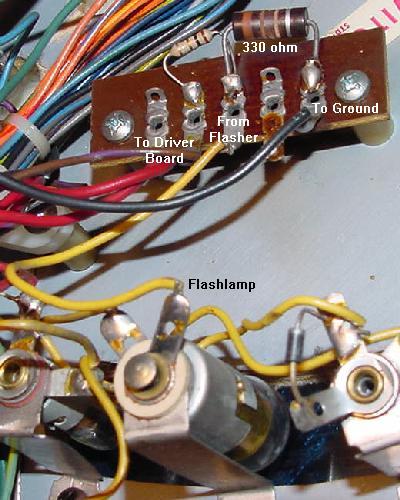

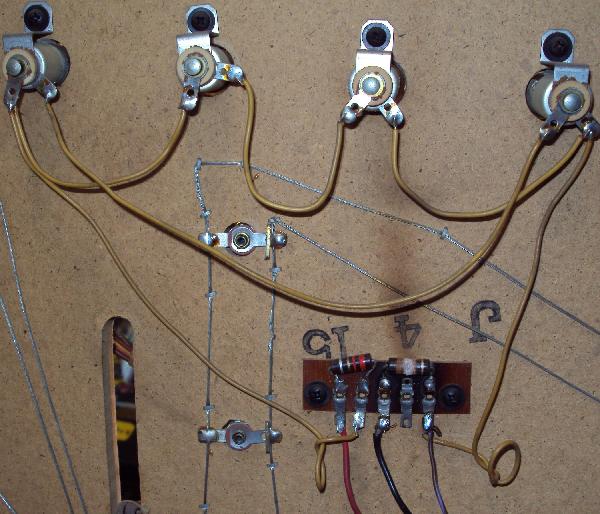

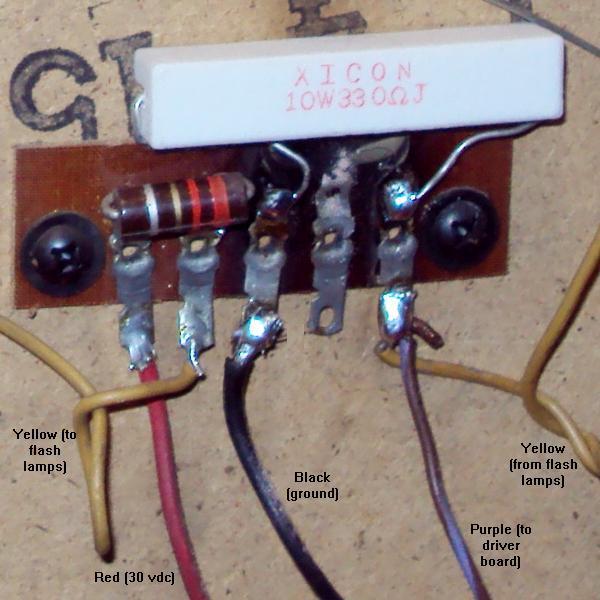

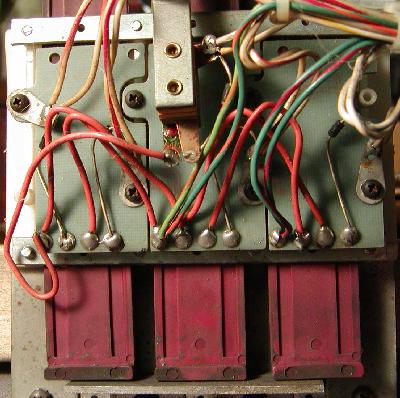

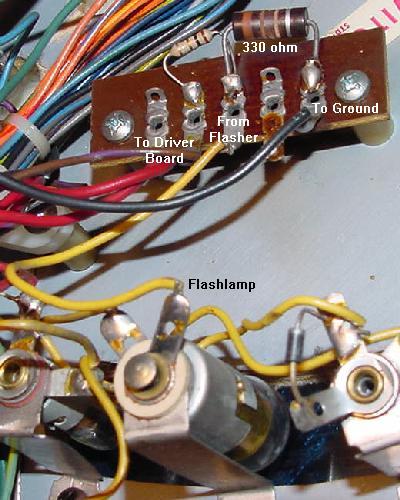

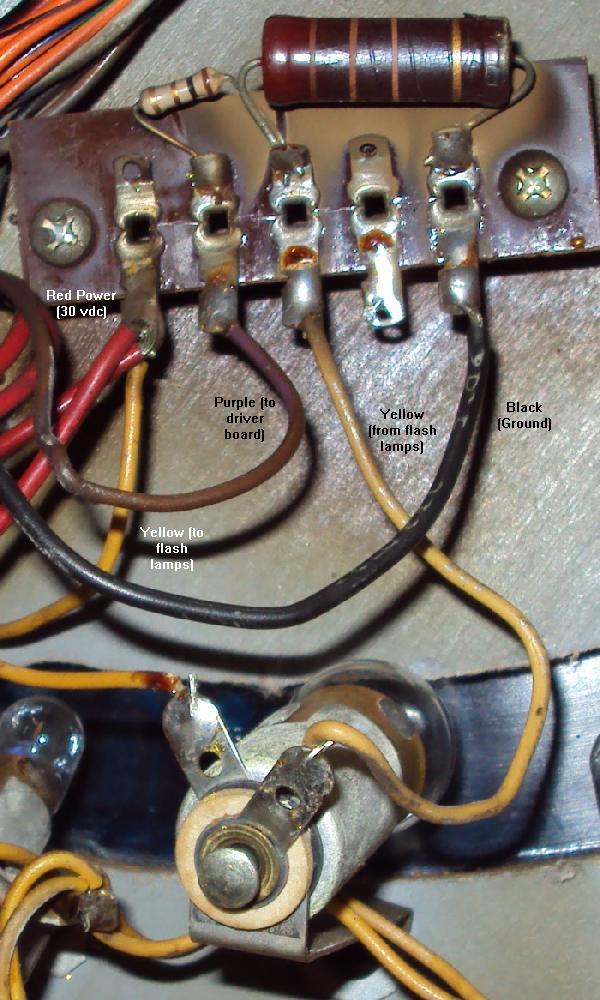

The resistor board for the flashlamp. The large 330 ohm 2 watt

resistor is permanently connected between the flash lamp & ground.

This keeps the flashlamp's filiment warm while the game is on,

letting 12 volts to the bulb all the time through the 330 ohm

resistor (this increase bulb life by keeping the filament warm).

When the flashlamp is fired by the game, ground is then completed

through the small 1 ohm (or 5 ohm) resistor, and the flashlamp

turns on brightly. Electricity takes the path of least resistance,

going through the 1 ohm resistor instead of the 330 ohm resistor.

The 330 ohm resistor is often burnt or desolders itself from its

board because power is going through it all the time (except when

the flash bulb actually flashes). This game is Firepower.

Williams used this bulb warming approach through System 11, but

abandoned it with WPC.

|

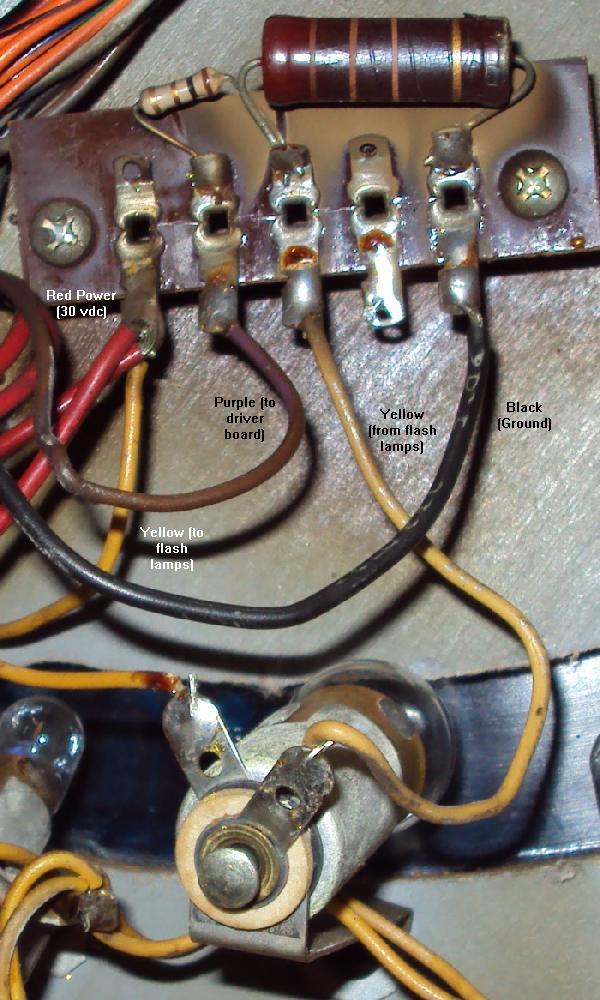

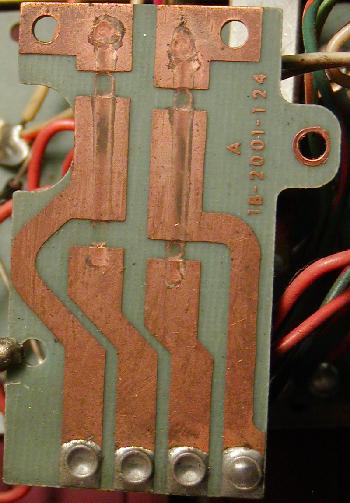

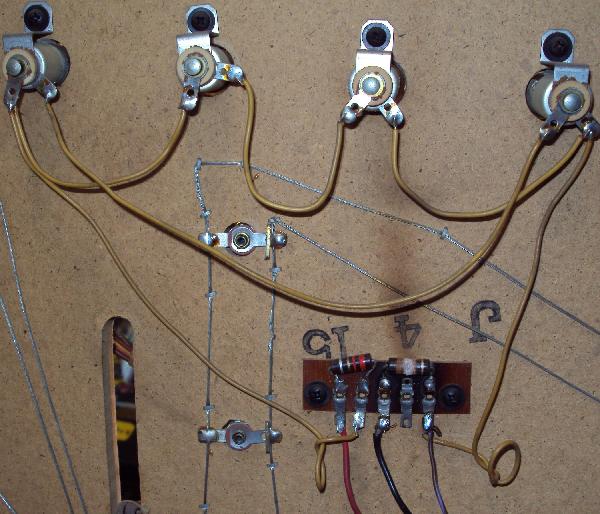

Another view of the flash lamp board on Firepower.

|

Flashers also have two resistors connected to them, one large 330 ohm

2watt, and one small 1 ohm (or 5 ohm) 1/2 watt.

When the flash lamps are not lit, the path to ground for the flash lamps

is completed via the large 330 ohm and smaller 1 ohm resistors together.

This keeps the bulb filiments warm

(and less likely to burn out and also more likely to give a BRIGHT flash).

On some flashlamps, they can look like they are glowing

slightly when not in use.

A cold flashlamp would take too long to get bright, so the flash would

have less impact, so that's why Williams did this.

When the driver board transistor is turned on,

the ground path is switched directly through the driver board, and the 330 ohm

resistor is essentially eliminated from the circuit

(because current will take the path of least resistance).

Note the 1 ohm resistor is still utilized.

Flash lamp board on Laserball. Note the wiring is a big different,

the the circuit is the same as used on Flash/Firepower (except the small

resistor is 2.2 ohms instead of 1 ohm.)

|

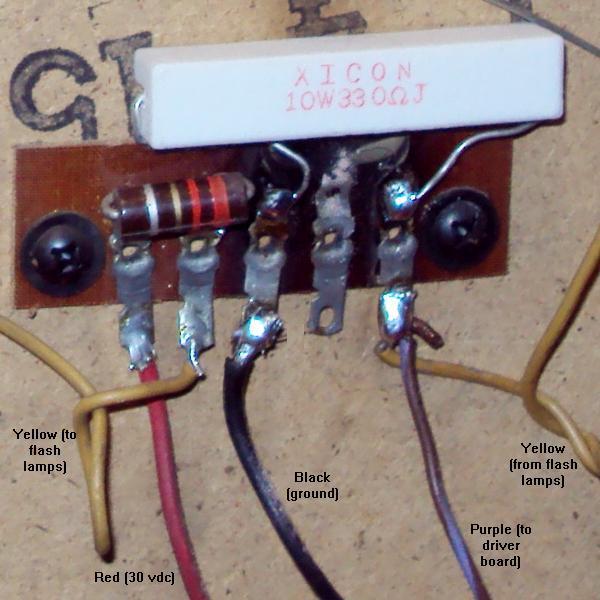

Close up of flash lamp board on Laserball, after the 330 ohm "warm up bulb"

resistor was changed to a 10 watt version (recommended.)

|

If a flash lamp is dull or sluggish, check the 330 ohm heater resistor.

These resistors do burn and break (or get cold solder joints, or

just fall off their solder terminal!), not allowing the flash lamp to "pre-heat".

If this happens, it won't pre-heat

the flash lamp, and the flasher may not flash!

Also if flash lamps burn out often, the 330 ohm resistor could be bad.

Be sure to check the 1 ohm (or 5 ohm)

resistor too, as these can go open, and neither flashlamp will work.

The wiring for Flashlamps and Coils. Note the two flashlamps in series, and the

330 ohm resistor path to ground, that keeps the flashlamps "warm" (and dim).

Then when the driver board ground path is used, the flashlamps turn on brightly,

as the 330 ohm resistor ground path is negated.

|

The Coil Diodes and Why they are Important.

After testing or replacing a driver board transistor, it is

important to examine the coil in the game. If any

coil (especially the one that was just locked on)

has a bad diode, this can almost instantly

kill its associated driver transistor! The coil diode

prevents a coil's collapsing voltage from "backwashing" to the

driver board, damaging the driver transistor.

Since you spent the time to test/replace the bad driver

board transistors, it only makes sense to also check for

bad coil diodes. Since these 1N4004 diodes are mounted

right to the coils under the playfield, vibration can crack

or damage them.

The best way to test a coil diode is to just grab the diode by

its body with the forefinger and thumb, and gently give

it a pull. If the diode has a cracked body or broken

lead, it should be pretty easy to see.

The 1N4004 coil diode mounted on a Firepower slingshot,

showing the proper orientation of the diode and power wires.

|

Coil diodes (1N4004) can be tested with a

DMM set to the diode function:

- Turn the game off.

- Unsolder or cut one end of the diode from the coil.

- Use a DMM set to the diode function.

- Put the blank DMM lead on the banded side of the diode.

- Put the red DMM lead on the NON-banded side of the diode.

- .4 to .6 volts should be seen.

- Reverse the DMM leads, and a null reading should be seen.

- If these values are not seen, replace the diode with a

new 1N4004 diode.

If a new diode is needed, remember to install it with the

diode's band on the power lug of the coil! It usually pretty easy

to tell which is the power lug of a coil. The power wire, which daisy

chains from coil to coil, is usually the thicker wire on a coil

lug. The banded lead of the 1N4004 diode should be connected to the

coil lug with this thicker daisy chained power wire attached.

The non-banded end of the diode attaches

to the coil lug with the thinner wire, which leads to the driver board transistor,

and ultimately ground.

3f. When Things Don't Work: Lamp Problems (the Lamp Matrix)

Introduction.

Remember, there are GI (General Illumination) lamps, and CPU controlled

(lamp matrix) lamps. The GI lamps come on as soon as the game power is

turned on. And these lamps generally do not turn off (except on Blackout, Scorpion

and System7 games, where there is a GI lamp relay to toggle all the GI

lamps on and off). The CPU controlled lamp matrix, when the game is

in attract mode (game over), will turn playfield and backbox lamps

on and off. The CPU controlled lamps also work during game play,

to light certain features to help the player.

The CPU controlled lamps (the "lamp matrix") uses +18 volts DC to drive the CPU

controlled lamps. If you're asking, "how do they use 18 volts to light

6.3 volt bulbs?", you would be asking a good question. While the lamp power supply

outputs a constant 18 volts DC from the backbox mounted bridge rectifier and

filter capacitor, the driver board "pulses" the 18 volts to the lamps.

This turns the lamps on and off very quickly, so that they never get to

full brightness, and are only on about 1/3 of the time (which roughly works

out to about 6 volts).

Turning the bulbs off and on like this increases light

bulb life, which is a nice feature since most operators don't change burnt out

lamps!

Important note about the lamp matrix: because the game is constantly pulsing

the lamp matrix to bring the 18 volts down to about 6 volts, these games

should NEVER be left on when they are "locked up". Because if they are locked

up, the lamp matrix is not strobing, which can burn out the playfield lamps

and COOK the driver board. The heat can get so bad on a driver board, that

it will start to desolder parts!

The lamp matrix power supply has only three components: a backbox mounted

35 amp 400 volt bridge rectifier, and very large 30,000 mfd filter capacitor,

and a fuse on the power supply board (F3).

There are some consistent lamp numbers from game to game.

For example, all system3 to system6 games consistently

used lamp column8 for the same functions (player up, tilt,

game over, etc.) With system7, Williams basically moved

column8 to column1. And with the last three system7

games (FirepowerII, Laser Cue, Starlight), this

changed yet again (still using column1, but the row order

changed). Below are the consistent lamps used in

system3-system6 and system7 (except Joust, FirepowerII, Laser Cue, Starlight)

lamp matrix:

Column/

Row |

Col. 1

Yel-Brn

2J5-8 |

Col. 2

Yel-Red

2J5-9 |

Col. 3

Yel-Orn

2J5-6 |

Col. 4

Yel-Blk

2J5-7 |

Col. 5

Yel-Grn

2J5-3 |

Col. 6

Yel-Blu

2J5-5 |

Col. 7

Yel-Vio

2J5-1 |

Col. 8

Yel-Gry

2J5-2 |

Row 1

Red-Brn

2J7-1 |

#1

Extra Ball

(sys7*) |

#9 |

#17 |

#25 |

#33 |

#41 |

#49 |

#57

Player1 Up

(sys3-6) |

Row 2

Red-Blk

2J7-2 |

#2

Ball in Play

(sys7*) |

#10 |

#18 |

#26 |

#34 |

#42 |

#50 |

#58

Player2 Up

(sys3-6) |

Row 3

Red-Orn

2J7-3 |

#3

Tilt

(sys7*) |

#11 |

#19 |

#27 |

#35 |

#43 |

#51 |

#59

Player3 Up

(sys3-6) |

Row 4

Red-Yel

2J7-4 |

#4

Game Over

(sys7*) |

#12 |

#20 |

#28 |

#36 |

#44 |

#52 |

#60

Player4 Up

(sys3-6) |

Row 5

Red-Grn

2J7-5 |

#5

Match

(sys7*) |

#13 |

#21 |

#29 |

#37 |

#45 |

#53 |

#61

Tilt

(sys3-6) |

Row 6

Red-Blu

2J7-6 |

#6

Hi-Score

(sys7*) |

#14 |

#22 |

#30 |

#38 |

#46 |

#54 |

#62

Game Over

(sys3-6) |

Row 7

Red-Vio

2J7-9 |

#7 |

#15 |

#23 |

#31 |

#39 |

#47 |

#55 |

#63

Shoot Again

(sys3-6) |

Row 8

Red-Gry

2J7-8 |

#8 |

#16 |

#24 |

#32 |

#40 |

#48 |

#56 |

#64

Hi-Score

(sys3-6) |

* Except Joust, Firepower II, Laser Cue, Starlight.

All the CPU Controlled Lamps Do Not Work.

Most CPU controlled lamp problems are driver board associated.

However if all the CPU controlled lamps are off and everything else is working,

check power supply fuse F3 and the voltage coming out of the power supply.

Using a DMM, measure the voltage from power supply connector 3J4 pin 5

to 3J4 pin 1 (ground). There should be 18 volts DC.

If there is no voltage (and fuse F3 is good), then chances are good that

the backbox mounted lamp matrix bridge rectifier 6BR1 has failed.

A Row or Column of Lamps does not Work, or is Locked On.

This problem is usually driver board related.

If a row or column is not working at all,

the first thing to try is to resolder the

.156" Molex male header pins on the driver board. The

solder joints on these often crack (from insertion/removal

of the connectors). This would include these driver board connectors:

- 2J4 (lamp matrix power)

- 2J5 (lamp matrix columns)

- 2J6 (lamp matrix ground)

- 2J7 (lamp matrix rows)

The next thing to suspect are the column/row transistors.

These can be tested with a DMM set to the diode function

and the game turned off. Keep in mind that column transistors die more

than row transistors.

Important Note: Testing transistors (or chips) using the methods below

does not give 100% proof that the component is good or bad!

It's probably about 95% accurate, but it is not 100% accurate

(especially with the transistor soldered into a board).

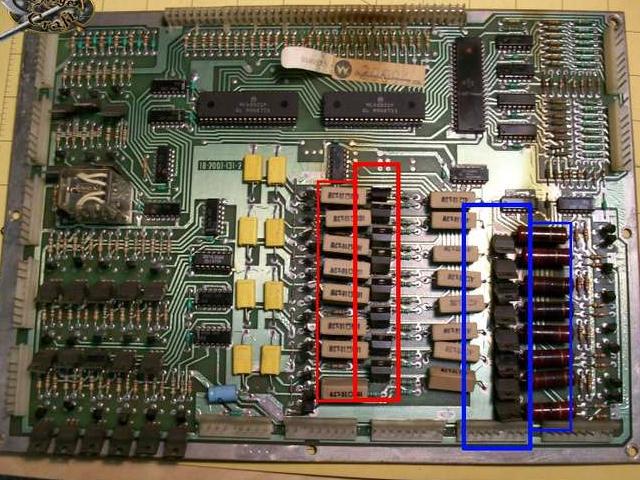

Lamp Columns (drive/strobe): test the TIP42, game off.

Q63, Q65, Q67, Q69, Q71, Q73, Q75, Q77.

Using a DMM set to the Diode function:

- Orient the transistor's writing facing towards you.

- Black DMM lead on *left* leg (base) of transistor.

- Red DMM on center leg (or metal tab), .4 to .6 volts seen.

- Red DMM on left leg, .4 to .6 volts seen.

Lamp Rows: test the 2N6122 (or TIP41), game off.

Q47, Q49, Q51, Q53, Q55, Q57, Q59, Q61.

Using a DMM set to the Diode function:

- Orient the transistor's writing facing towards you.

- Read DMM lead on the *left* leg (base) of transistor.

- Red DMM lead on the center (collector) leg (or metal tab), .4 to .6 volts seen.

- Red DMM lead on the right (emitter) leg, .4 to .6 volts seen.

Driver board or Playfield Problem?

Say you have a game where, in attract mode,

colums 4 through 8 are very bright and the top four resistors on

lower right side of driver board are getting warm.

If you start a game and some lamp matrix lights stay locked-on, and some will

still strobe like in attract mode. Is the problem on the playfield

(shorted socket diode, mis-wired, or shorted lamp socket), or on the driver board?

To determine where the problem is, with the game on,

remove the lamp column connector 2J5 and lamp row connector 2J7

from the driver board (the row and column connectors).

Leave the lamp power 2J4 and lamp ground

2J6 connectors in place. Jump any one of the four

overly-bright columns pins on 2J5 to any lamp row connector pin on 2J7

using two alligator clip leads and a light bulb (#47 or #44). If this single

bulb is still overly bright, then the problem is on the driver

board. If the lamp lights normally, there are two

lamp column wires shorted together somewhere on the

playfield.

Testing a Lamp Row/Colums with the Game On.

Another way to test the lamp rows (and indirectly the

columns) is to do this:

- Turn the game on.

- Press the manual-down/auto-up coin door button to manual-down.

- Press the advance coin door button once. The score displays

should go blank.

- Press the advance coin door button again. The score displays

should all show zeros.

- Using a alligator test lead, attach one end to ground

(the grounding braid in the bottom of the backbox

or pin 40 of the interboard connector).

- Touch the other end of the alligator test lead to any

one of the driver board transistors Q47, Q49, Q51,

Q53, Q55, Q57, Q59 or Q61 (these are all in a vertical row

in about the center of the driver board).

- All the corresponding playfield lamp matrix row lights should

all turn on (eight lamps in all). If less than eight light,

refer to the operator's guide and see which lamps in the particular

row are not turning on, and make a note of it.

- Move the alligator test lead to the next lamp matrix row

transistor to test the next eight row lamps.

If several lamps did not turn on, check the operator's

manual and see if all eight lamps are in the same column or row.